MAKING PROCESS

The Albariño variety, synonymous with quality and one of the great varieties in the world, is the only variety that we work with at this winery. A respectful and pampered vintage is accompanied by the most modern winemaking techniques, which together with its conservation process, result in wines with their own personality in a winery marked by passion. Our production calendar is always that of the Rías Baixas area, which is usually carried out between the months of August and September, depending on weather conditions, to proceed with its production throughout the year. The product obtained is a young, fruity white wine, with a graduation of between 12 and 14 degrees, protected by the DO Rías Baixas. For the elaboration of our wines we maintain a careful process. These are the steps:

1º Control of Maduration. The objective of this operation is to determine the optimum moment of beginning of the harvest. For this, the probable alcoholic degree of the grapes and the total acidity of the must are analyzed.

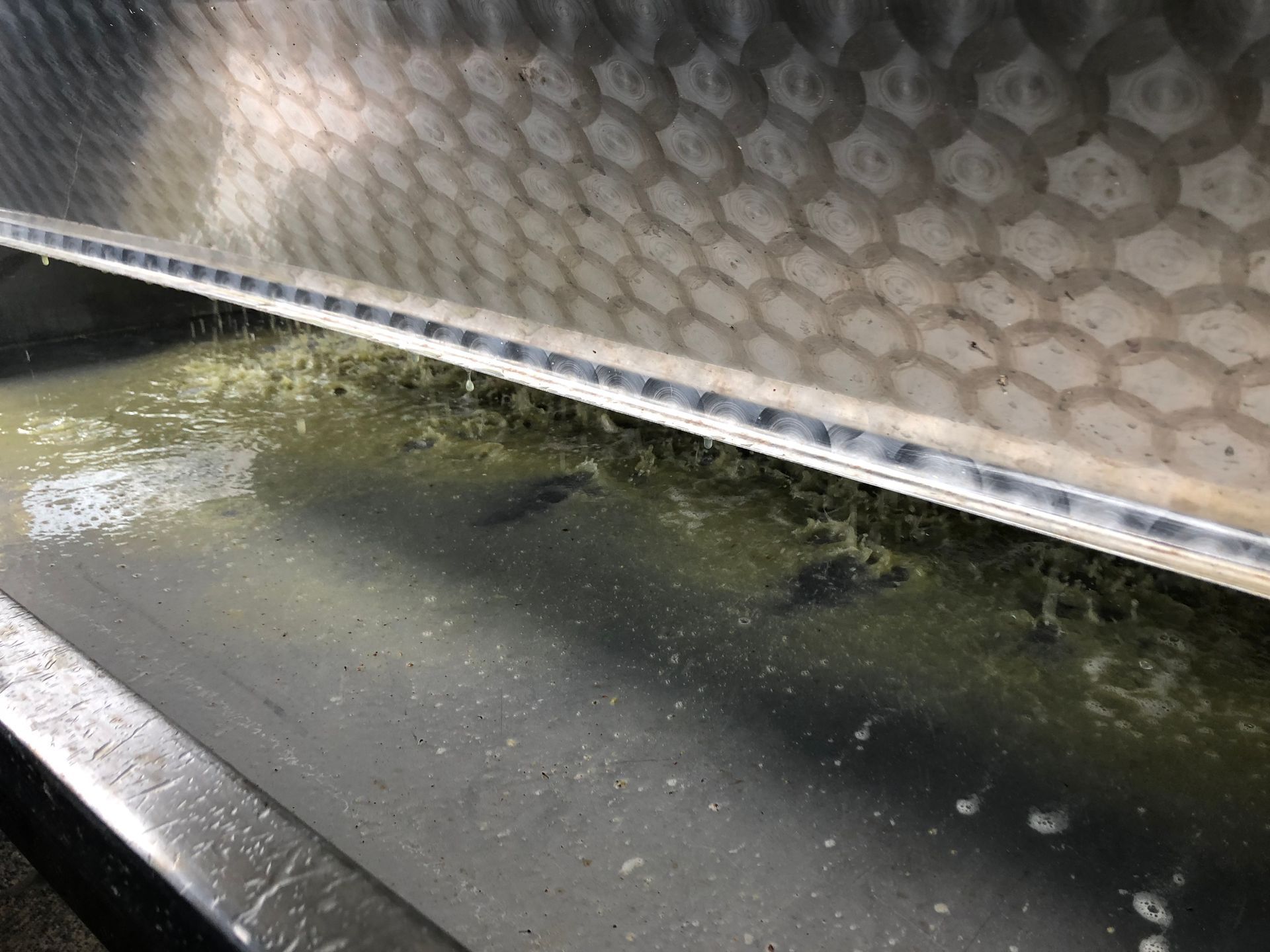

2º Harvest. Once the harvest calendar has been established, those vineyards whose grapes contain the best graduation and the most controlled acidity are harvested first. The grapes arrive in small boxes that are immediately analyzed and taken to the selection tables where a group of people remove those bunches that do not meet the quality criteria. Right then it goes to the destemmer and then goes through a tubular heat exchanger to lower the temperature of that already selected grape to about 7ºC before it goes to the macerators. In the absence of oxygen, the grapes will remain in contact with the must for a few hours, extracting aromas. The objective of the cold maceration technique is to extract the characteristic varietal aromas from the skin cells. This step is optional and is not always used.

3º Pressing. Its mission is to extract the must by means of the pressure exerted on the grapes. This operation is usually carried out in the Rías Baixas with pneumatic presses.

4º Settling. Operation that consists of cleaning the must, separating it and stripping it of the coarser particles it may contain. In the Rías Baixas, static racking using cold is widely used.

5º Alcoholic fermentation. It is usually carried out in stainless steel tanks and at a controlled temperature of around 16ºC.

6º Racking. Process with which, once the fermentation is finished, it is the wine is separated from the lees as quickly as possible. Later is when the mixtures and coupagge of the wines are made.

7º Tartaric Stabilization. This process is intended to eliminate tartaric precipitations. It is made by subjecting the wine to a temperature of around -4ºC for 7 to 10 days. Then it is filtered.

8º Bottling. The bottling normally begins in mid-February. The wine spends a month in the bottle before going on the market.